Each time involved grooved pipe design and manufacturing, associating with qualified consultants is important. These experienced enhanced tube fabrication experts possess a intensive perception of thermal dispersion principles, matter traits, and the modern practices for creating reliable heat exchangers. They manage everything from initial design and experimental assembly to high-volume generation and meticulous examination. Deciding on the right fin tube building master can greatly influence the performance and shelf life of your machinery.

Superior Textured Conduits

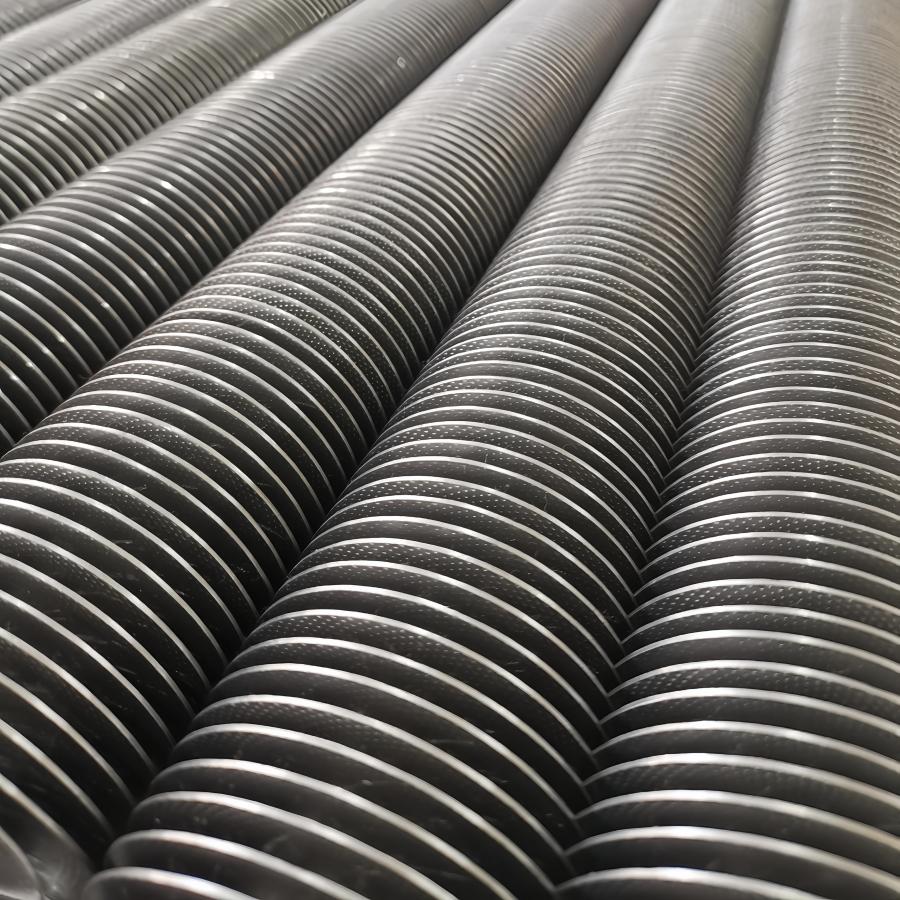

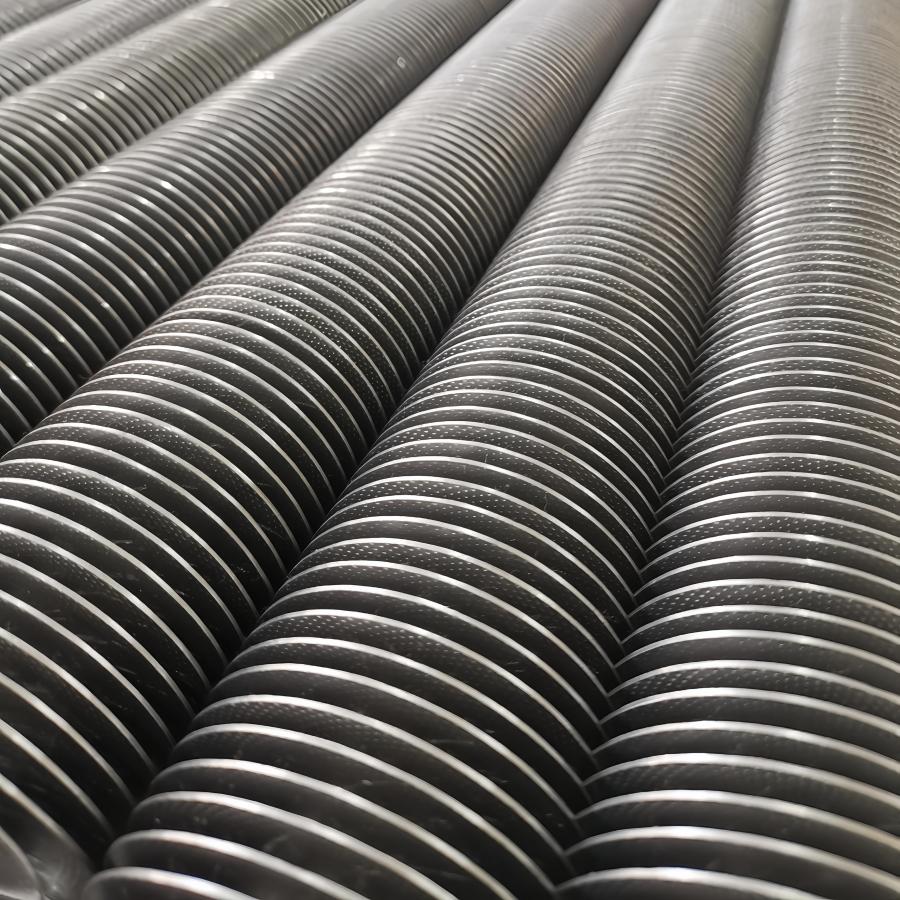

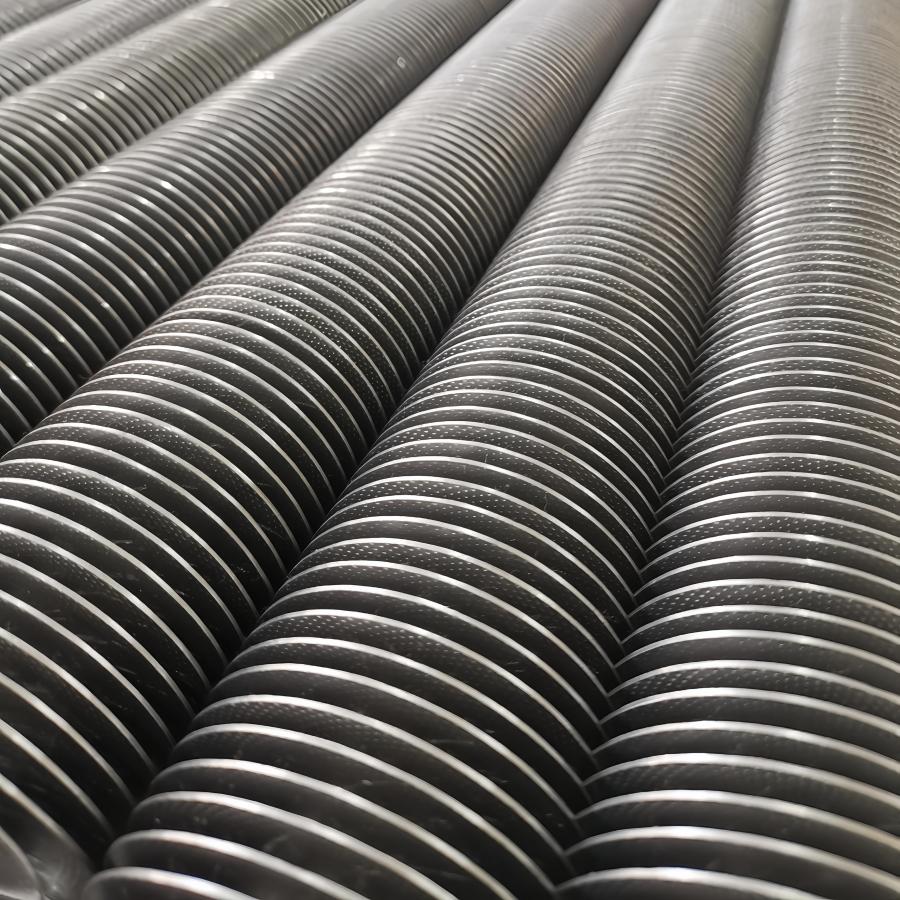

Industrial factory implementations frequently demand remarkably efficient warmth transmission, and high-performance finned pipes are indispensable to achieving this. These parts incorporate intentionally designed rib geometries, customarily applying involved designs to maximize the region available for heat movement. Production procedures may involve pressing, preceded by careful fin fabrication and at times a particular surface coating to besides boost efficiency. Selecting the ideal finned pipe format is dependent on the exact utilization parameters, namely medium qualities, caloric measures, and stress intensities.

Custom Extended Metal-based Pipe Designs

Meeting challenging heat-related management needs? Our dedicated team creates engineered copper pipe offerings precisely designed for your application. We use advanced manufacturing techniques and accurate calculations to enhance warmth spread efficiency. Whether you're in the automotive sector, or need superior cooling within a delicate facility, our improved copper pipe can provide increased effectiveness. We appraise factors such as substance conveyance rates, adjacent temperatures, and structural constraints designed for assemble a truly singular and effective solution.

Masters in Textured Aluminum Tube Methods

For several years, we've been dedicated to providing unparalleled expertise in finned aluminum tube design, manufacturing, and deployment. As leading experts, we offer a comprehensive range of services, catering to a broad spectrum of industries, including heating and cooling, energy production, and chemical processing. Our team of expert engineers displays a thorough understanding of heat distribution principles and matter science, ensuring that every undertaking we undertake delivers optimal efficiency and longevity. We value ourselves on delivering specialized answers that precisely required our clients’ unique demands. Whether you require heat exchanger repair, installation, or a holistic system configuration, our focus to excellence remains unwavering. Reach us today to consider your distinct issues.

Expanded Tube Assembly and Consulting Offerings

Refining temperature exchange efficiency is paramount in countless realms, and that's where specialized improved tube fabrication and advisory provisions truly shine. We supply comprehensive tools encompassing everything from initial creation to full-scale deployment. Our unit of experienced professionals leverage advanced simulation techniques and area best standards to design specialized finned tube modules for a wide array of demanding environments. Whether you're seeking to enhance effectiveness, lessen power costs, or address specific system challenges, our improved tube expertise ensures maximum results. We also offer periodic support aid to maintain extended operational integrity.

Progressive Precision Augmented Tube Creation

The conditions of modern heat radiating systems are prompting a change towards highly expert augmented tube processes. Traditionally, fundamental fin layouts were satisfactory, but now applications in electronics and manufacturing processing necessitate particularly tight tolerances and complex geometries. This involves meticulous manufacturing of fins directly onto the tube blank, often utilizing cutting-edge iced working equipment to attain the desired projection size, distance, and form. Over and above, the substance selection plays a important job, with particular metals frequently applied to increase thermal operation while maintaining structural durability. Benchmark testing mechanisms are also paramount to verify regular grooved tube rating.

Enhanced Copper Pipe for Heat Exchangers

Cutting-edge heat movement systems frequently leverage finned copper pipeline as a crucial component in heat exchangers. The inclusion of fins, generally made from light metal, significantly expands the surface region available for heat conduction, leading to a increased efficient heat circulation. These textured copper pipelines are generally found in applications ranging from factory processes, such as heat regulation machinery, to occupational HVAC systems. The top thermal conductivity of copper, combined with the u bend tube stretched surface coverage provided by the fins, culminates in a particularly effective method for supervising heat. Different fin styles, including even and circular, deliver varying degrees of performance improvement depending on the precise application’s conditions.

Cutting-edge heat movement systems frequently leverage finned copper pipeline as a crucial component in heat exchangers. The inclusion of fins, generally made from light metal, significantly expands the surface region available for heat conduction, leading to a increased efficient heat circulation. These textured copper pipelines are generally found in applications ranging from factory processes, such as heat regulation machinery, to occupational HVAC systems. The top thermal conductivity of copper, combined with the u bend tube stretched surface coverage provided by the fins, culminates in a particularly effective method for supervising heat. Different fin styles, including even and circular, deliver varying degrees of performance improvement depending on the precise application’s conditions.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum textured tubes offer a compelling combination of slim construction and remarkable output, making them ideal for a extensive range of process heat transfer systems. Their unique structure—featuring aluminum fins attached to the tube coat—significantly enlarges the heat exchange power without adding substantial weight. This translates to lower energy costs and improved overall performance trustworthiness. Consequently, these tubes are frequently preferred in HVAC units, refrigeration, and other heat exchanging processes where minimizing density and maximizing warmth transfer are paramount aspects.

Finned Tube Substrate Options: Red Metal & Lightweight

When favoring finned tube fabric, engineers frequently scrutinize copper and aluminum. Copper offers exceptional degradation withstand and superior caloric conductivity, making it optimum for applications where high-performance heat transfer is paramount, such as in climate control systems. However, copper's raised valuation and probable for galvanic corrosion with other minerals can be limiting factors. Conversely, aluminum provides a significantly lower rate and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Refining Heat Transfer with Finned Sections

The productivity of heat apparatus frequently hinges on the design and realization of finned tubes. These structures significantly enhance the surface area available for heat convection, allowing for a much greater dispelling of heat compared to simple, unfinned pipes. The boost process involves a complex interplay of factors, including fin shape – such as fin scale, spacing, and gauge – as well as the element of both the fins and the foundation sections themselves. Careful consideration of the medium flow characteristics, whether it's air or a substance, is also paramount to ensure that the heat removal isn’t restricted by boundary layer effects or uneven dispersal of the working mass. Ultimately, a well-designed finned conduit array delivers a meaningful improvement in overall thermal output within a given space.

Sturdy Finned Tube Solutions for Technical Applications

Overcoming the needs of demanding technical environments necessitates long-lasting heat dispersion assemblies. Our finned tube products are engineered for exceptional durability, providing dependable heat dispersion in a range of applications, from fuel processing to environmental control. Constructed from superior materials and featuring advanced wear endurance techniques, these elements minimize upkeep downtime and maximize operational capability. The unique fin design promotes augmented heat diffusion, even under difficult operating circumstances.