creative corrugated box producer how do dedicated corrugated box developers enhance product shelf life?

Explore the intriguing domain of corrugated carton production through this in-depth manual. We shall examine the essential phases in transforming simple paper into sturdy boxes that preserve items during conveyance. Comprising flute formation, printing, and finalizing, we shed light on the nuances of this crucial market.

- Learn about the various forms of corrugated cartons and their unique uses.

- Review new breakthroughs in packaging production.

- Understand the environmental impact of corrugated box production and potential solutions.

Whether a pupil, technician, or industry aficionado, this manual offers useful insights into the ever-evolving corrugated carton market.

Constructing Ideas with Corrugated Paperboard

Corrugated paperboard, commonly disregarded as plain protective fabric, acts as a flexible tool for design. Its solid essence backs the assembly of fresh constructions and styles, including practical containers to artistic ornaments. With cleverness, one can shape this conventional material into something extraordinary.

List the endless possibilities of corrugated cardboard crafting by:

- Testing assorted tactics like snipping, folding, and layering

- Employing repurposed materials for a sustainable strategy

- Revealing your pieces to influence others

With its affordability, accessibility, and versatility, corrugated cardboard is a perfect material for crafting enthusiasts of all ages and skill levels. Tap into your artistic side and allow your innovation to soar using this modest material.

The Fusion of Engineering and Aesthetics in Corrugated Boxes

Corrugated box fabrication merges an engaging integration of technical skill and artistic vision. It goes beyond simple construction; it entails creating a protective shell that protects merchandise in shipment while also making a significant impact on audiences.

A seasoned planner recognizes the elaborate features of corrugated sheet, adjusting its dimension, flute design, and layout to address distinct specifications of each item.

- In addition, artistic elements are critical.

- A thoughtfully created container is quickly distinguishable on display, grabbing the notice of intended consumers.

- In essence, carton design balances safeguarding and attractiveness.

Addressing Requests: Growing Your Box Production

As your company thrives and requests increase, it's vital to guarantee production meets client requirements. Elevating box production could facilitate steady functioning and strengthen reputable status.

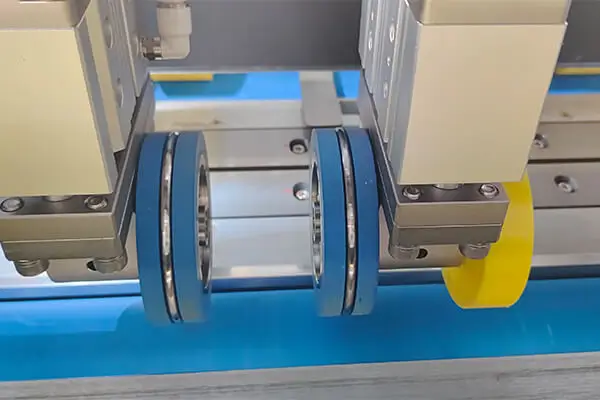

At outset, consider your operational systems. Analyze your existing equipment and workforce to identify potential bottlenecks or areas that need improvement. Subsequently, research ways to augment manufacturing scale. Reflect on obtaining updated technology or refining current gear to raise efficiency.

Consider that boosting volume is subordinate to enhancing full production line. Integrate optimized manufacturing systems to lessen discard and improve resource allocation. Perfect operations, computerize customary jobs, and emphasize workforce development to create a competent group.

Eventually, strengthen enduring relationships with purveyors to copyright stable supply lines. By implementing these strategies, you can successfully scale your corrugated box production and meet the growing demand of your customers.

Enhancements in Packaging Technology

The packaging domain unremittingly grows, sparked by necessities for sustainable, streamlined, and pioneering tactics. Corrugated paperboard, a trusted product for ages, sees resurgence powered by innovative advancements. From lightweight designs to integrated features, corrugation is embracing the future. Creators examine cutting-edge paths to refine packaging operations, implementing green resources and methods. The consequence is a stream of innovative packaging plans altering the sector panorama.

These innovations address key challenges facing businesses, such as reducing waste and optimizing logistics. Shoppers also take advantage of these developments, using packaging that is tougher and more practical. The outlook for corrugated materials is promising, rich with possibilities for greener and more effective packaging systems.

Environmentally Responsible Corrugated Cartons: Eco Options

Corrugated packaging serves as an essential element in current distribution systems. Typically constructed from pulp, such parcels possess notable consequences for the ecosystem. Even so, heightened appreciation for eco-conscious strategies involves producing parcel goods. Luckily, fresh ideas are at hand to raise environmental responsibility of these cases.

A vital component embraces applying recycled pulp. Using assembly or consumer remains, the demand for virgin components drops, preserving natural habitats and resources.

Likewise, suppliers allocate funds to earth-friendly production systems. These actions cover refining electricity use and lowering discard within fulfillment flows. Customers may contribute by selecting cartons verified as eco-friendly. Look for labels such as FSC or SFI, which guarantee responsible sourcing and manufacturing.

By following these procedures, we protect boxes as significant economic contributors while decreasing environmental strain.

Ensuring Excellence in Corrugated Box Production

Gaining high standards in carton production counts on precise evaluation techniques. Beginning with material acquisition and ending with product evaluation, all stages need constant vigilance. Exacting rules guide all processes to ascertain each case complies with leading parameters.

- Examining base substances for flaws, durability, and consistency is vital to avoiding future issues.

- Respecting precise proportions and thresholds in trimming and molding ensures cartons are structurally robust and apt for purpose.

- Repeated review of design application maintains colorful imagery and readable text

- Integrating robotic inspection technologies improves productivity and precision in quality checks

Via focusing on quality assurance in all phases, fabricators supply containers that are robust and aesthetically pleasing. This focus on superior quality fulfills buyer hopes and bolsters business standing.

Corrugated Box Printing: Branding and Impact

Packaging graphics printing constitutes an essential part of brand visibility. As shoppers see your item, the carton turns into a prime platform for creating a statement. A well-designed print on a corrugated box can engage attention, communicate your brand's identity, and ultimately influence purchasing decisions.

Besides, packaging branding furnishes numerous ways to customize your shipments. By means of striking pigments to original graphics, you can demonstrate brand personality through carton design.

Finally, box printing surpasses simple purpose – it functions as a valuable avenue to fortify brand identity and interact with consumers.

From Raw Material to Finished Product: The Corrugated Box Journey

The formation of a container is a fascinating series transforming raw inputs into an important shipment and protection solution. The process initiates by acquiring pulp, often sourced from reused stock. Thereafter, pulp turns into panels of corrugated pulpboard, with a ridged center enclosed by two smooth liners.

These panels are carefully shaped per exact requirements, then joined with dedicated equipment to form the intended carton outline. Glues serve a key function in bonding pieces firmly, providing a sturdy and resilient configuration.

In conclusion, containers experience detailed testing measures to verify durability and alignment with trade regulations.

Coming from straightforward foundations, the shipment materializes as a durable packaging creation, intended to protect many goods throughout shipment.

Global Container Market: Movements and Chances

The worldwide carton industry undergoes a phase of expansion. corrugated box maker This robust segment is encouraged by rising customer demands for protection. Major causes comprise increase of web-based trade and necessity for green parcels