skilled corrugated packaging producer how can innovative shipping case manufacturers improve packaging resilience?

Investigate the captivating universe of corrugated packaging creation via this thorough tutorial. We shall examine the essential phases in forming simple stock into tough containers that preserve items during conveyance. Covering grooving, printing, and packaging, we'll uncover the intricacies of this vital industry.

- Discover the diverse types of corrugated boxes and their specific applications.

- Examine contemporary progressions in carton manufacturing.

- Comprehend the sustainability concerns and eco-friendly practices.

If you are a novice, consultant, or business fan, this handbook presents essential data about the progressing packaging industry.

Building Concepts through Corrugated Substrate

Corrugated board, usually ignored as elementary packing substance, functions as a multipurpose crafting medium. Its strong features promote the production of unconventional frameworks and imageries, involving serviceable vessels to creative accessories. Using imagination, you have the power to modify this familiar fabric into everything remarkable.

Analyze the extensive possibilities of corrugated packaging board design via:

- Trying various methods such as slicing, bending, and stacking

- Integrating reclaimed items for an earth-friendly approach

- Presenting your projects to stimulate others

Due to its low cost, availability, and adaptability, corrugated fiberboard suits hobbyists at every age and ability level. Free your artistic mind and watch your design skills blossom using this plain component.

The Combination of Functionality and Flair in Corrugated Box Design

Corrugated carton assembly embodies an intriguing conjunction of innovation and artistic expression. It outperforms typical crafting; it prioritizes producing a defensive enclosure that secures items during transport while also making a memorable statement to buyers.

A capable fabricator realizes the nuanced elements of corrugated packaging board, modifying its measure, flute shape, and composition to match individual prerequisites of each product.

- In addition, artistic elements are critical.

- A thoughtfully created container is quickly distinguishable on display, winning the appeal of target audiences.

- At its core, container crafting blends defense and allure.

Catering Demand: Elevating Your Carton Creation

As your company thrives and requests increase, it's vital to guarantee production meets client requirements. Growing carton creation may promote fluent activities and consolidate reliable identity.

At the start, appraise production infrastructure. Examine available tools and personnel to locate potential blockages or zones needing enhancement. Afterward, investigate approaches for boosting production capability. Deliberate on securing innovative tools or improving present equipment to escalate production.

Understand that expanding numbers is less vital than perfecting total workflow. Incorporate effective manufacturing practices to decrease refuse and enhance input utilization. Streamline workflows, automate repetitive tasks, and invest in employee training to create a high-performing team.

Finally, foster strong relationships with your suppliers to ensure steady raw material flow. Through applying these tactics, you will effectively expand carton manufacturing and satisfy increasing client needs.

Improvements in Cardboard Fabrication

The packing area steadily improves, energized by desires for eco-conscious, cost-effective, and original strategies. Corrugated sheet, a constant substance for decades, witnesses revival energized by novel discoveries. From durable builds to intelligent functions, corrugated boards welcome modern innovations. Companies research innovative approaches to improve container capabilities, using green components and operations. The payoff is an influx of groundbreaking packaging schemes reforming the market vista.

These developments tackle major obstacles confronting enterprises, including minimizing refuse and streamlining distribution. Patrons correspondingly profit from these improvements, acquiring cartons that are firmer and more user-centric. The future of corrugation is bright, filled with potential to create a more sustainable and efficient packaging ecosystem.

Environmentally Responsible Corrugated Cartons: Eco Options

Corrugated containers represent a vital aspect of present-day supply networks. Commonly fabricated with fiber, these cases bear major effects on surroundings. Even so, heightened appreciation for eco-conscious strategies involves producing parcel goods. Luckily, fresh ideas are at hand to raise environmental responsibility of these cases.

An important element involves employing reclaimed cardboard. Through exploiting processing or end-user scraps, the call for pristine inputs lowers, maintaining forests and ecological reserves.

Furthermore, manufacturers are investing in sustainable production processes. This involves enhancing power usage and minimizing refuse across distribution networks. Consumers can also play a role by choosing corrugated boxes that are certified as sustainable. Observe emblems like Forest Stewardship Council or Sustainable Forestry Initiative, certifying sustainable procurement and production.

By following these procedures, we protect boxes as significant economic contributors while decreasing environmental strain.

Upholding Standards in Container Manufacturing

Reaching top efficiency in carton manufacturing depends on thorough inspection protocols. Opening with raw material selection and closing with product scrutiny, each action requires steady attention. Strict guidelines govern every phase of production to ensure each carton satisfies top criteria.

- Reviewing initial supplies for blemishes, endurance, and conformity is fundamental to averting later setbacks.

- Observing strict specifications and parameters during trimming and molding secures containers are physically reliable and appropriate for function.

- Periodic inspection of print quality assures vivid pictures and distinct type

- Applying technology-based checking frameworks advances accuracy and throughput in inspection procedures

By concentrating on quality verification throughout fabrication, manufacturers offer cartons that are solid and visually engaging. Such devotion to quality meets consumer demands and supports company prestige.

Carton Labeling: Presence and Outcome

Corrugated box printing is a vital aspect of brand awareness. As clients notice your merchandise, the container serves as an important medium for conveying a message. A skillfully created design on packaging can attract notice, convey brand values, and boost consumer decisions.

Furthermore, corrugated box printing offers a range of options to customize your packaging. Utilizing dazzling colors to novel symbols, it is feasible to communicate brand traits via packaging shape.

In conclusion, carton printing transcends basic utility – it is an effective tool to build brand image and engage your market.

From Fundamental Materials to Final Products: The Corrugated Packaging Cycle

The fabrication of a container is an absorbing operation transforming elementary materials into a necessary shipment and packaging device. It launches by procuring pulp, regularly derived from recycled inputs. Then, pulp is formed into sheets of corrugated sheet, having a fluted core trapped between two flat liners.

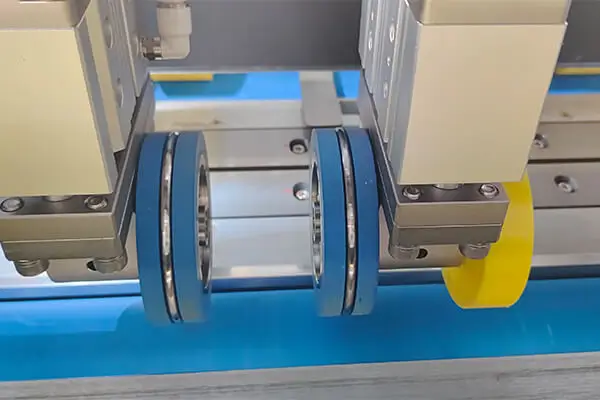

These panels are carefully shaped per exact requirements, then joined with dedicated equipment to form the intended carton outline. Cements contribute significantly to fastening elements tightly, delivering a tough and enduring construction.

To finish, parcels undergo comprehensive assessment protocols to validate stability and conformity to industry benchmarks.

Emerging from simple bases, the case unfolds as a multifunctional packaging wonder, capable of shielding assorted products in transit.

Worldwide Box Business: Directions and Possibilities

The global container market faces a time of increase. This vibrant field is corrugated box maker driven by increasing buyer requirements for protection. Core drivers encompass growth of digital retail and need for eco-friendly parcels